Automotive Insulation

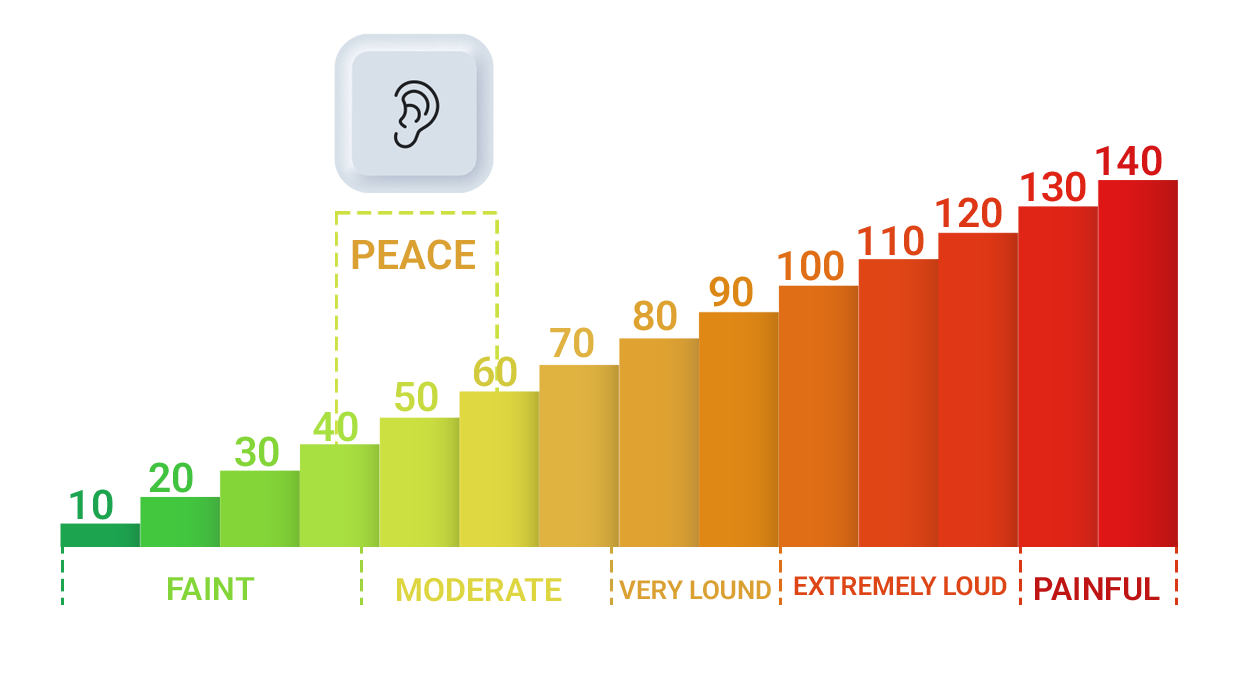

More and more with the advancement of technology, people spend their time in their cars and automobiles. A sonic force of more than 80 decibels will damage the ears.

Such a noise is not only bad for the driver’s health, but also exposes him to safety risks. In addition to the driver, other occupants of the car as well as people outside the car and residents of the alley and street are also exposed to the noise caused by noisy cars. A sonic range for cars that will maintain inner and outer peace and comfort is in the range of 45-65 to DB.

In the design of a car’s interior, in addition to physical protection, the interior also acts as a barrier to the penetration of noises and unwanted sounds with beauty and style in the design.

Automotive NVH Sources

In addition to the beauty of the room, automobile manufacturers also consider issues such as NVH, weight and strength. NVH is an abbreviation of three words: Noise, Vibration, and Harshness.

Automotive NVH Sources

“Turbulences” caused by the non-aerodynamic design of the car body in the face of air flow is the biggest source of vibration in a moving car.

These “turbulences” penetrate through the aperture, glass, pillar frame and the HVAC of the car. In cars such as a Rolls Royce, thick and double-glazed glass is used for this purpose. In economy cars, this issue is minimized in the design. For example, side mirror glare in a car like the Nissan Leaf is minimized by a different and complex headlight design, as well as by insulating the HVAC ducts. This air-borne factor is the main cause of vibration in the seat, steering wheel and center mirror of the car.

Car parts such as the gas pump and the noises of electrical parts and even an electric engine have the least contribution to the noise.

Vehicles are noisy environments in general, but the important thing is that they are not the type of noise that can be heard. All sockets, enginess, generators, drivers and even the wire tree will cause major noises without protection or a “Shield” that can disturb the communication systems inside the car. Therefore, for Ethernet or ECU communication waves to work, disturbing sound or “Noise” with a level of 10 kHz to 600 MHz must be injected “Noise” level in the different components and system levels. This topic has gained much importance nowadays since smart cars are becoming more and more trendy.

Not only the brake, engine and powertrain, but also the road and tires are the sources of noise in the car.

According to the study and the Pareto law, the following four factors are the most annoying noise sources in the car:

1- Engine

2- Exhaust system

3- Fuel system

4- HVAC system

One of the most important issues for improving the comfort standards of the driver and the passengers is to isolate the interior of the car from any sound pollution caused by the force of driving and the car’s power transmission system.

Currently, various materials are used in order to reduce the sound transmission from inside the engine compartment and the power transmission system to the cabin. The combination of two or more layers of the following materials, in addition to creating an obstacle in the sound transmission, also prevents the heat and cold transmission inside the cabin:

Heavy Micro-Expanded Polymer Layer

Flexible Polyurethane foam Layer

Non-Woven Layer + Polyurethane Foam

Glass Fiber

Today, these materials are suitable substitutes for felt and heavy layer products due to the following competitive advantages:

Lighter weight to reduce fuel consumption and emissions

Higher performance in drop and face absorption for greater silence

Capabilities beyond sound such as very low heat and cold transfer efficiency

Low flammability at self-extinguishing level for passenger safety

Production speed from design to installation for car manufacturers

Competitive price to reduce consumer cost

Low emission leading to increased health factor for passengers due to being oil-free and Bitumen-free

kian Group Car insulation

After conducting joint research with major international suppliers, Kian Group has gained the ability to produce all kinds of sound absorbing and reducing insulations by achieving the highest classes. And now it provides these insulations for car manufacturers to use inside the passenger cabin and engine compartment.